- Products

- Automotive

- Avionics

COTS Module

- Zynq RFSoC ADC DAC PCIe Card

- Agilex 7 SmartNIC Card

- ZU19/17/11 PCIe SmartNIC Card

- Kintex-7 PCIe Card

- PCIe to SD 3.0 M.2 Module

- Zynq ZU7/ZU5/ZU4 3U-VPX

- Virtex UltraScale+ 3U VPX

- Kintex UltraScale+ 3U VPX

- Zynq ZU19/17/11 3U VPX

- Kintex-7 3U VPX Card

- PCIe Gen3 x8 FMC Module

- Quad QSFP28 FMC+ Module

- PCIe Gen4 x16 FMC+ Module

- FMC Add-On Cards

- FPGA IP

- ODM Solutions

- Custom Design

- Resources

- Company

Get a Quote

Please fill in the form and we will get back to you soon!

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Get in Touch

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Thank you for subscribing to our newsletter!

Case Study: ZU19EG SoM for LiDAR

Manufacturers and automakers are racing to design cars that drive themselves, reducing accidents and improving traffic flow. LiDAR is a key technology poised to power this revolution. LiDAR uses laser pulses to generate a 3D map of the surroundings of the vehicle in real-time. LiDAR systems begin by identifying the smallest object that needs to be detected and its reflectivity, with resolution as a key system characteristic. Creating real-time point clouds is one of the major challenges of a LiDAR system

.

A deep-tech company in the automotive vertical approached iWave with a requirement for a high-speed FPGA platform required for processing the input data from LiDAR Sensors powering the next generation of ADAS and autonomous driving systems.

Key Challenges for a LiDAR Platform

- Requirement of high-speed transceivers and a high number of DSP slices

- Ability to interface with a wide range of sensor modalities

- Scalable Deep Learning Processing Unit (DPU) for advanced AI perception with ultra-low latency processing

- Capability to implement pre- and post-processing algorithms on high-bandwidth sensor data

- Short lead times for the production of the processing platform

- High-speed interfaces like MIPI, JESD204B, LVDS, and GigE, as well as low bandwidth sensor standards such as CAN, SPI, and I2C

ZU19 Zynq UltraScale+ MPSoC System on Module Features

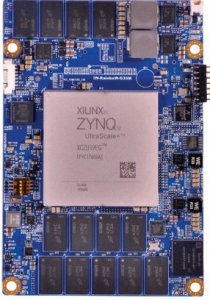

With the above challenges and requirements in mind, iWave proposed the System on Module based on the XILINX Zynq UltraScale+ ZU19 MPSoC.

- Quad Core Cortex-A53 MPCore @ 1.5GHz

- Dual Cortex-R5 MPCore @ 600MHz

- 1.1M programmable logic cells

- -1 Speed Grade Support

- 16 x High Speed transceivers @ 32.75Gbps

- 32 x High Speed transceivers @ 16.3Gbps

- 4 x PS transceivers @ 6Gbps

- 142 User Configurable IOs

- Peripherals: Ethernet, PCIe, USB3.0, SATA3.1, Display Port

How the ZU19 Adaptive SoC enables LiDAR Solutions

- The Image data can be transferred via GTH transceivers within Programmable Logic (PL), enabling high-speed connectivity and data transmission.

- Partitioning between software and associated hardware acceleration functions using the high bandwidth connectivity between the processing system and PL allows for parallel processing, reducing clock speed and power dissipation

- 1968 DSP Slices that offer advanced DSP capabilities produce rich point cloud images with depth, signal, and ambient data used for high resolution for object detection

The XILINX Adaptive SoC platform provided by iWave allows for flexible programming while providing scalable and flexible processing performance for complex sensory data while providing the required low latency and high-throughput capabilities. Complexities in MPSoC system design such as complex IO banks voltage handling and high-speed DDR memory design are taken care of in the System on Module designed by iWave.

With the system on module incorporating the above designs and considerations, customers can now focus on the core competencies and features of their product, helping them reduce time to market with reduced development cost. iWave Systems and other system-on-module manufacturers take responsibility for product longevity while maintaining the end of life for the modules’ hundreds of components.

The processing element can be configured to meet the processing and I/O needs of the sensor configuration, software framework, and system performance requirements. A LiDAR sensor can produce about a terabyte per second (TB/s), approximately 1012 bytes, which is converted to about 20Gb/s before processing. This is still a large amount of data that requires a lot of processing power. The Arm Cortex R5 real-time processing unit is used to implement safety-critical functionality for monitoring the LiDAR system in real-time.

The iWave ZU19 System on Module is a powerful and flexible platform that delivers advanced capabilities needed for lidar sensors: signal processing, point cloud pre-processing, and point cloud machine learning acceleration. The System on Module also helps speed up your product development cycle.

With our system on modules portfolio, iWave is driven by the mission to be a reliable technology partner in their product journey and ensure the best of products and extensive technical support. iWave System is a global leader in designing and manufacturing highly Scalable FPGA & SoC Systems on Modules and computing platforms.

With over 21 years of experience in FPGA-based solution design and development and a key focus on industrial, medical, and automotive industry verticals, iWave is committed to being your reliable technology partner. iWave helps customer shorten their product design and development cycle through a wide portfolio of embedded solutions.

For more details, contact us at mktg@iwavesystems.com

Keep reading

iWave is an embedded systems engineering and solutions company, designing solutions for the Industrial, Medical, Automotive and Avionics vertical markets, and building on our core competency of embedded expertise since 1999. Read More…

Newsletter

Copyright © 2022 iWave Systems Technologies Pvt. Ltd.