- 製品紹介

- 自動車

- 航空電子工学

FMCカード

- VITA 57.4 FMC+ Loopback Test Module

- VITA 57.4 FMC+ Loopback Test Module

- VITA 57.1 FMC Loopback Test Module

- VITA 57.1 FMC Loopback Test Module

- PCIe Gen4 x8 FMC Module

- PCIe Gen4 x8 FMC Module

- PCIe Gen4 x16 FMC+モジュール

- PCIe Gen4 x16 FMC+モジュール

- PCIe Gen3 x8 FMCモジュール

- クアッド QSFP28 FMC+ モジュール

- PCIe Gen3 x8 FMCモジュール

- クアッド QSFP28 FMC+ モジュール

- FMCアドオンカード

- FMCアドオンカード

COTSモジュール

- Agilex 7 SmartNICカード

- Zynq RFSoC ADC DAC PCIeカード

- ZU7/ZU5/ZU4 PCIe SmartNIC Card

- ZU7/ZU5/ZU4 PCIe SmartNIC Card

- ZU19/17/11 PCIe SmartNICカード

- ZU19/17/11 PCIe SmartNICカード

- PCIe Switch Module

- PCIe to SD 3.0 M.2モジュール

- PCIe Switch Module

- PCIe to SD 3.0 M.2モジュール

- Kintex-7 PCIeカード

- Kintex-7 PCIeカード

- Zynq ZU7/ZU5/ZU4 3U-VPX

- Zynq ZU7/ZU5/ZU4 3U-VPX

- Virtex UltraScale+ 3U VPX

- Virtex UltraScale+ 3U VPX

- Kintex UltraScale+ 3U VPX

- Kintex UltraScale+ 3U VPX

- RFSoC 3U VPX

- RFSoC 3U VPX

- Agilex 9 3U VPX

- Zynq ZU19/17/11 3U VPX

- Zynq ZU19/17/11 3U VPX

- Kintex-7 3U VPXカード

- Kintex-7 3U VPXカード

- VITA 57.4 FMC+ Loopback Test Module

- VITA 57.4 FMC+ Loopback Test Module

- VITA 57.1 FMC Loopback Test Module

- VITA 57.1 FMC Loopback Test Module

- PCIe Gen4 x8 FMC Module

- PCIe Gen4 x8 FMC Module

- PCIe Gen4 x16 FMC+モジュール

- PCIe Gen4 x16 FMC+モジュール

- PCIe Gen3 x8 FMCモジュール

- クアッド QSFP28 FMC+ モジュール

- PCIe Gen3 x8 FMCモジュール

- クアッド QSFP28 FMC+ モジュール

- FMCアドオンカード

- FMCアドオンカード

- IP Cores

- ODMソリューション

- カスタムデザイン

- Company

お見積もり

フォームにご記入ください!

アイウェーブにご連絡いただきありがとうございます。

担当者よりご連絡させていただきます!

お問い合わせ

アイウェーブにご連絡いただきありがとうございます。

担当者よりご連絡させていただきます!

ニュースレターのご購読ありがとうございます!

FPGA System Design: Why Choose FPGA SoM for Optimal FPGA System Design

There is an increasing need for FPGAs with a rise in applications such as data centers, high performance computers, medical imaging FPGAs, precise layout traces, special PCB materials, form factor limits, and thermal management.

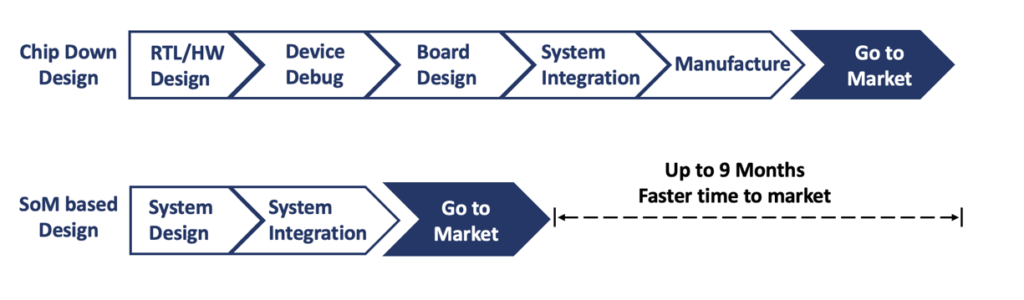

Hardware designers previously were option a “chip-down” architecture, where specific silicon devices are chosen, and a fully customized circuit board is developed for the application. While this does produce a highly optimized implementation, it can take significant development time and cost to reach production readiness. To save the expense and time of a chip-down development, design teams are now considering a more integrated solution such as Multi-Chip Module (MCM), System-in-Package (SIP), Single-Board Computer (SBC), or a System-on-Module (SoM).

The FPGA SoM market is growing at a rapid pace, and is enabling a wider range of users to adopt FPGA-based platforms than ever before. FPGA-based SoMs are widely adopted in many applications due to their adaptable architecture and ease-of-use design.

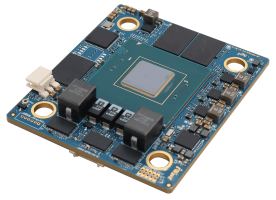

An Overview of an FPGA System on Module

An FPGA System on Module is a compute module like an Single Board Computer but designed to connect into a larger solution, rather than be standalone. An FPGA System on Module contains all the essential components such as high-speed DDR memory, flash storage, power management, common interface controllers and board support package (BSP) software. A SoM supports high-speed transceiver blocks, and multiple communication protocols, including Ethernet, USB, and PCIe, ensuring seamless connectivity and integration into various systems.

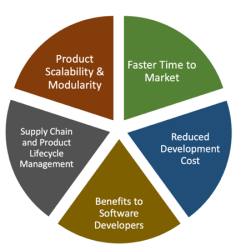

A System on Module (SoM) approach gives product designers and solutions architects a head start. It uses a pre-built module with core computing parts and software. You only design the carrier board with the necessary components and connectors, which can also be outsourced. This way, R&D can focus on your company’s specific needs. SoMs are production ready and offer several benefits that are highlighted in the picture and spoken about in detail through the following sections. Through an FPGA SoM, component sourcing is simplified, leading to more predictable design-cycles and business results.

Time-To-Market

A SoM based approach involves a shorter development time, and fewer mistakes during the development cycle which can help get to market faster. The System on Modules are all pre-tested and qualified by manufacturers such as iWave, and enables designers to implement faster in their products. Companies can focus on their unique value proposition and core competencies, rather than worry about the design complexity of the System on Modules.

The picture above illustrates the time advantage on considering a System on Module in the product design lifecycle. A SoM approach also allows for the design to be changed late in the design process

Development Cost and Complexity

A production ready and qualified SoM reduces the design complexity, which enables fewer errors in the design process. The faster time to market helps in reducing the overall development and qualification costs for the company. During the design of the System on Module, the module undergoes EMC compliance test and several rugged tests such as thermal cycling, aging, stress, etc. This ruggedness allows adapting the system on modules to the product with ease and assured performance.

Product Modularity and Scalability

The SoM approach for the FPGA SoCs further allows greater scalability for the end applications in terms of logic density, FPGA IOs, and a number of transceiver lanes. For example, a well-designed carrier board design architecture can cover system IO ports for multiple end products ranging from the an FPGA with 192K logic cells to an FPGA with 1.1M logic cells. Also, the SoM approach allows migrating new generation SoC solutions without changing the product mechanical architecture and key carrier board design. FPGA-based SoMs allow you to adapt to evolving requirements by using reprogrammable hardware with custom carrier boards. This allows for lower development effort compared to a full hardware redesign from scratch.

Supply Chain and Product Lifecycle Management

An FPGA System design involves hundreds of components, which requires the supply chain and procurement teams to interface with a large number of suppliers and co-ordinate pricing and delivery. Through a SoM approach, iWave and other SoM companies take the responsibility of maintaining a steady supply chain through forecasting with key suppliers and maintain a steady supply. This helps in better production lead times and better product pricing, since the SoM vendors are better able to manage economies of scale.

Another key advantage in a SoM centric approach is the ease of product lifecycle management. With the EOL notice from the suppliers and the necessity to update designs based on the component availability, a SoM approach removes this complexity in the system design. The SoM vendors have a dedicated team to manage the hardware and software updates required on the SoM due to component obsolescence and feature enhancements.

Benefits to Software Developers

The SoMs are all available with a pre validated BSP and design examples that can help you get started quickly. With System on Modules, you can develop application software on the same production-ready hardware that you develop on, without needing to port your design from a development kit.

With the above advantages, A System on Module based FPGA System Design approach provides several advantages for companies and help them focus on their core competencies.

iWave SoM Portfolio

iWave works with leading FPGA vendors such as AMD, Altera and Achronix, with early access to the latest technology and building an extensive portfolio of System on Modules and COTS Modules.

- AMD

- iW-RainboW-G35M: ZU19/ZU17/ZU11- Zynq UltraScale+ SoM

- iW-RainboW-G30M: ZU7/ZU5/ZU4- Zynq UltraScale+ SoM

- iW-RainboW-G47M: Kintex UltraScale+ FPGA SoM

- iW-RainboW-G52M: Virtex UltraScale+ SoM

- iW-RainboW-G57M: Versal AI Edge/Prime SoM

- iW-RainboW-G42M: Zynq UltraScale+ RFSoC SoM

- iW-RainboW-G65M: ZU15/ZU9/ZU6- Zynq UltraScale+ MPSoC SoM

- iW-RainboW-G36M: Zynq UltraScale+ MPSoC ZU5/ZU4/ZU3T/ZU3/ZU2/ZU1 SoM

- iW-RainboW-G63M: Versal Premium SoM

- Altera

- iW-RainboW-G58M: Agilex 5 SoC FPGA SoM

- iW-RainboW-G43M: Agilex 7 SoC FPGA SoM

- iW-RainboW-G51M: Agilex 7 R24C SoC FPGA SoM

- iW-RainboW-G45M: Stratix 10 SoC FPGA SoM

- iW-RainboW-G24M: Arria 10 SoC FPGA SoM

- iW-RainboW-G24M: Arria 10 FPGA SoM

- アクロニックス

- iW-RainboW-G64M: Speedster7T SoM

In addition to the portfolio of FPGA System on Modules, iWave also enables customers with FPGA Design Services such as Carrier Board Design, FPGA IP development, porting, and customization, Linux and BSP Porting, certifications and mechanical design.

iWave is an embedded systems engineering and solutions company, designing solutions for the Industrial, Medical, Automotive, and Avionics vertical markets. Building on a core competency of embedded expertise since 1999, iWave boasts of an extensive portfolio of high-performance FPGA and SoC FPGA System on Modules and embedded computing platforms enabling customers in their product development journey.

You can contact the iWave sales team at mktg@iwave-global.com.